Upright RV LLC. partners with JG Lubricants and Horizon labs to employ the latest in analytical technology which provides you with comprehensive insights into the condition of your machinery. With a focus on precision and reliability, our expert team delivers actionable results that can help you:

Prevent Costly Repairs by identifying potential issues before they escalate into major problems.

Enhance Performance through tailored recommendations for optimizing your machinery's operation.

Extend Equipment Lifespan by ensuring fluids are in peak condition, reducing wear and tear on vital components.

Improve Safety by eliminating the risk factors associated with equipment failure, keeping your team safe and operations smooth.

Partnering with Upright RV LLC means investing in the longevity and reliability of your fleet. Let us help you achieve unparalleled operational efficiency with our lab grade fluid analysis services. Trust us to be the guardians of your machinery's health, enabling you to focus on what you do best—building and transporting the foundations of our future.

BOOK YOUR Analysis today.

The most important reason for oil and coolant analysis is to prevent equipment failure by identifying potential problems before they lead to significant damage or complete breakdowns. This proactive approach allows for timely maintenance and repairs, ultimately saving costs, extending equipment lifespan, and ensuring operational reliability. Here's a breakdown of why this is crucial:

Predictive Maintenance

Early Problem Detection: Analysis can detect contaminants, metal particles from wear, and chemical imbalances that signify internal issues, allowing for early intervention.

Maintenance Scheduling: Instead of relying on generic schedules, maintenance can be performed based on actual condition, preventing unnecessary services or delays in addressing emerging issues.

Cost Savings

Avoiding Major Repairs: Catching issues early typically means less expensive repairs compared to the cost of major overhauls or replacing irreparably damaged equipment.

Optimizing Oil Change Intervals: Knowing exactly when oil or coolant needs changing can prevent wasting resources on too-frequent changes and avoid damage from waiting too long.

Equipment Longevity

Reducing Wear and Tear: Properly maintained oil and coolant systems protect against excessive wear and overheating, directly contributing to longer equipment life.

Operational Efficiency: Equipment that runs in optimal condition performs better, uses fuel more efficiently, and faces fewer operational hitches.

Safety and Compliance

Enhanced Safety: Preventing equipment failure on the job protects operators and prevents accidents.

Regulatory Compliance: Regular analysis can help ensure compliance with industry regulations concerning equipment maintenance and operation.

In essence, oil and coolant analysis is a cornerstone of modern maintenance strategies, embodying the principle of "an ounce of prevention is worth a pound of cure." It not only protects your investment in machinery but also supports safety, efficiency, and compliance objectives.

FAQs

- Fluid Analysis Services -

Q1: What types of fluids can you analyze? A1: Our expert team is equipped to analyze a variety of fluids, including engine oils, hydraulic fluids, transmission fluids, and coolants. Our advanced lab facilities are prepared to offer detailed assessments, providing you with a thorough understanding of your machinery’s internal health.

Q2: How often should I have my fluids analyzed? A2: The ideal frequency for fluid analysis varies based on equipment usage, operational intensity, and specific manufacturer recommendations. Typically, for high-demand machinery in the construction and trucking sectors, bi-annual analysis is advisable. For a consultation tailored to your fleet, please reach out to us directly.

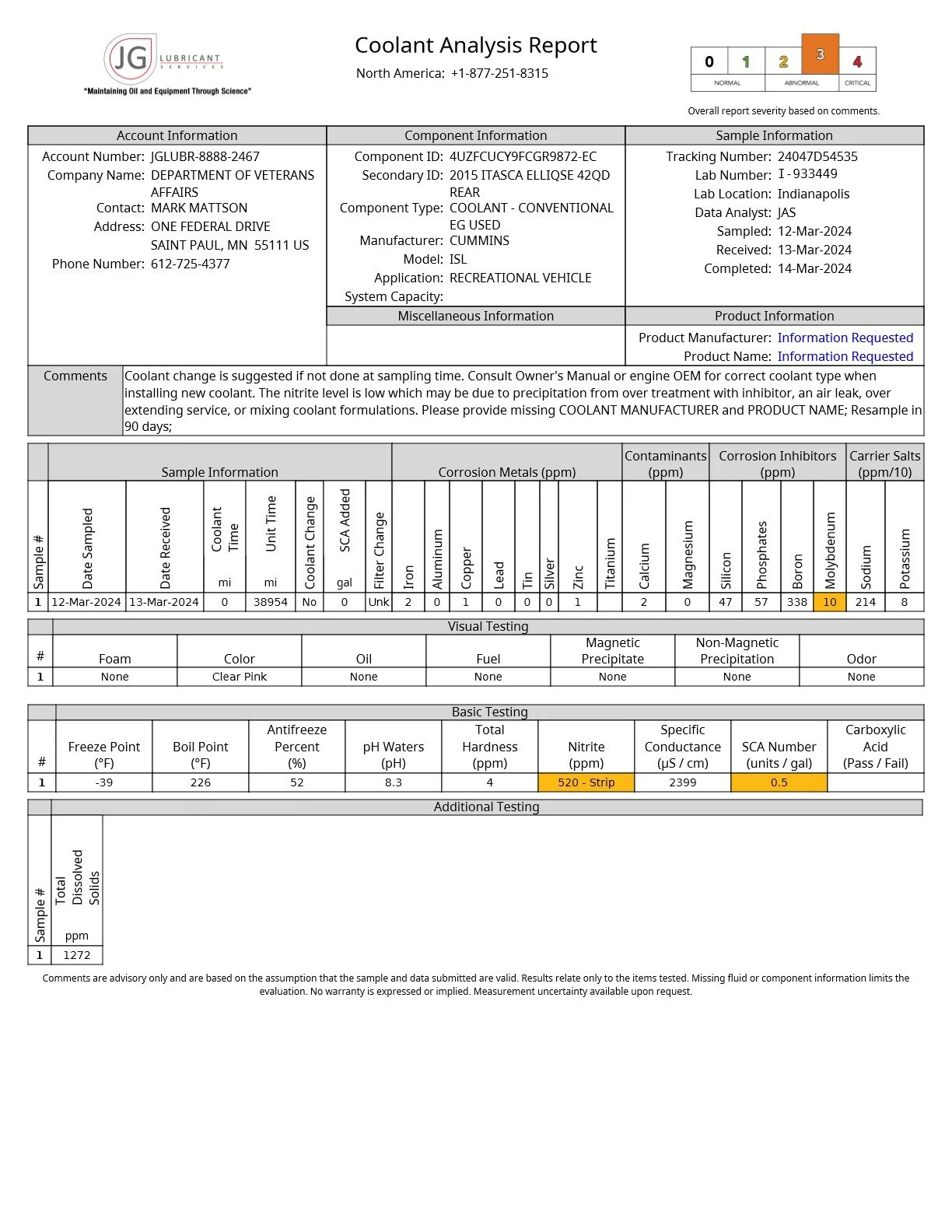

Q3: What insights can fluid analysis provide about my equipment? A3: Fluid analysis acts as a critical diagnostic tool, identifying wear metals, contamination levels, and the fluid’s chemical condition. These insights can pinpoint early signs of wear, contamination ingress, or fluid breakdown, aiding in preemptive maintenance strategies to avert machinery failures.

Q4: How quickly are analysis results provided? A4: Our commitment is to minimize your operational downtime, offering analysis results within 24-48 hours from the time of sample collection. Should you require faster turnaround, expedited service options are also available.

Q5: Can fluid analysis truly prevent equipment failure? A5: Yes, indeed. Adopting regular fluid analysis as part of your maintenance routine can drastically diminish the likelihood of sudden equipment breakdowns. Early detection allows for timely maintenance interventions, preventing minor issues from evolving into costly failures.

Q6: How does the mobile on-site sample collection process work? A6: Our convenient mobile on-site service means we come to you. Our professionals will arrive equipped to collect samples directly from your equipment, ensuring the process is hassle-free and conducted with the highest standards for accuracy. This service is designed to save you time and effort, allowing you to focus on your core operations while we handle all aspects of the fluid sampling process.

Q7: What differentiates your fluid analysis service? A7: Leveraging state-of-the-art technology and expert analysis, we deliver precise, actionable results. Our dedicated team specializes in the Recreational Vehicle, Construction and Trucking industries, ensuring our services are directly aligned with your needs. Our mobile on-site collection service sets us apart, offering unparalleled convenience and efficiency.

Q8: How do I initiate your fluid analysis services? A8: Starting is simple. Reach out to us via our website, email, or phone to discuss your needs. We’ll arrange a visit from our mobile collection service at a time that suits your schedule, making the process as seamless and convenient for you as possible.